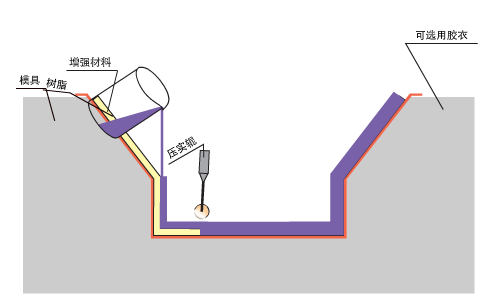

The mold is evenly coated with release agent and gel coat resin, and then the reinforcement material is laid. The resin mixed with curing agent is coated with pressing roller and brush to make the resin impregnated with reinforcement material and remove bubbles. The laying operation is repeated until the design thickness of the product is reached, and then it is solidified under normal temperature or heating conditions.