The basic process of molding process is to put a certain amount of pre-treatment molding material into the preheated die, and apply higher pressure to fill the mold cavity. Under the predetermined temperature conditions, the molding material gradually solidified in the mold cavity, and then the SMC product was taken out from the die, and then the necessary auxiliary processing was carried out to obtain the final product.

The molding process of sheet molding compound (SMC) is to cut the required SMC into the required shape, remove the protective films on both sides, stack them according to certain requirements, and then place them in the appropriate position of the mold, and then heat and pressure mold according to the specified process parameters.

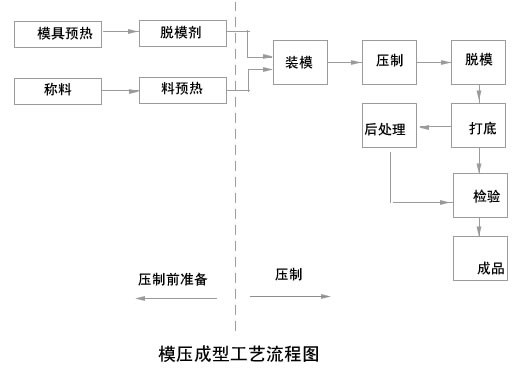

The pressing process of composite molded products (as shown in the figure) the process of forming products in the mold cavity after the pressing materials are installed in the mold cavity in the presence of curing agent or heating. Molding temperature and molding pressure affect the quality of SMC products. The best molding temperature, molding pressure and holding time should be determined under the comprehensive consideration of various influencing factors.